EthonAI Secures CHF 6.27M Seed Funding

On 14 February 2023, EthonAI reported that it had raised CHF 6.27M in seed funding, led by Earlybird Venture Capital and La Famiglia. Incorporated only a year ago, the ETH spin-off provides manufacturers with AI-based defect detection and analysis software.

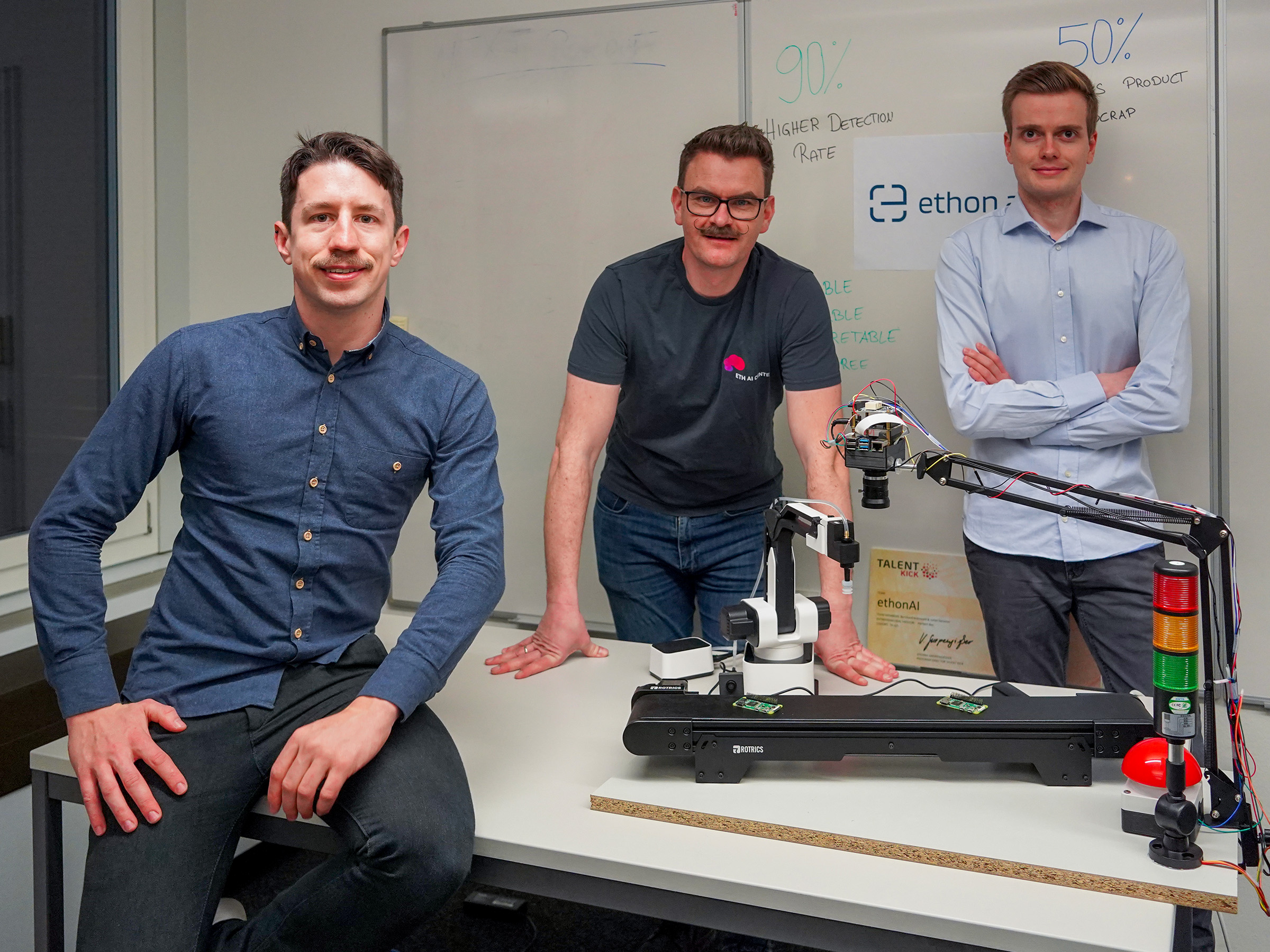

In the year since its incorporation, EthonAI has quickly become one of ETH Zurich’s fastest-growing AI spin-offs. Earlier this year, the team – now over twenty members strong – secured seed funding worth CHF 6.27M, led by Earlybird Venture Capital and La Famiglia with participation of existing investors, Wingman and Acequia Capital.

EthonAI provides a software platform that uses machine learning to detect, monitor and prevent quality losses in manufacturing. “We are thrilled to have the support of Earlybird and La Famiglia as we continue to grow and expand our product platform,” says CEO Dr Julian Senoner. He and Dr Bernhard Kratzwald founded EthonAI right after their doctoral graduation, together with their former Professor Torbjørn Netland, who heads the Chair of Production and Operations Management at D-MTEC.

Disrupting decades of convention

Poor quality is a massive cost driver in manufacturing. It makes up a significant portion of production costs – estimated at around 20 percent of sales revenue – and risks damaging brand reputation and harming the environment.

Despite this, not much innovation has taken place in the field in recent years, according to Netland. “The quality management practices used in manufacturing stem from decades-old research: Statistical Process Control (SPC) originated in the Bell Labs during the 1920s, Design of Experiments (DoE) was developed for agricultural purposes over a century ago and Acceptance Sampling was introduced during World War II. It is not that these methods are bad,” says Netland, “but for one thing, manufacturers struggle to use them effectively, and for another, they don’t take advantage of the revolutionary developments that have taken place in computer technology and data science.”

Easy to use, easy to scale

EthonAI is now on a mission to upend history and bring quality management in manufacturing into today’s digital age of AI and code-free user experience. The platform offers software tools for vision-based defect detection, process monitoring and root cause analysis that don’t require process engineers and quality managers to write a single line of code.

Vision-based defect detection reduces the risk of poor-quality products reaching customers. “In many industries, detecting defects is still a highly manual process,” says Netland. “EthonAI compares images taken at the production line with cameras and uses heatmaps to highlight potential defects to a human inspector. The inspector can then decide what to do with the defective part. EthonAI thereby helps inspectors be more productive and successful at their jobs. Visual inspection technologies are not new, but EthonAI’s unsupervised anomaly detection is a game-changer in terms of speed, accuracy and accessibility.”

Reacting to defects once they exist is one thing; EthonAI’s software goes one step further and helps manufacturers avoid defects from arising altogether by identifying their origin during the manufacturing process. The platform aggregates quality data – like that collected using vision-based defect detection – and process data, such as timestamps, product IDs, temperatures, tool pressure, vibration and more. “When all these data are collected, it can be said to be a digital representation of the physical processes – or digital shadow,” says Netland. “If the critical processes are well represented by these data, this is a perfect setting for machine-learning algorithms, which can find complex patterns in huge amounts of data and match predictors to an outcome variable, such as a defective product.” In contrast to the black-box functionality of many AI tools, EthonAI lets users know how it finds patterns and guides engineers to the processes that are most likely to be critical for improvement.

Picking up speed

One year after its incorporation, EthonAI has already acquired leading manufacturers, including Siemens, Roche, and Lindt & Sprüngli, as its customers. The spin-off reports that companies using its technology have seen significant increases in productivity and report an over-50-percent reduction in quality losses.

“EthonAI has the potential to revolutionise the way manufacturers manage quality, and we are glad to back the team on their mission,” says Earlybird Partner Dr Andre Retterath. Judith Dada, a Partner from La Famiglia, adds to the praise: “After having looked at dozens of companies in the space, we finally became convinced that the team behind EthonAI has what it takes to win in this market. We are excited to be a part of the company’s journey as it continues to grow and succeed.”

Securing such exceptional funding after just a year in business is consistent with EthonAI’s ambitious, forward-looking approach. CEO Julian Senoner already has his mind on what lies ahead: “With this funding, we can bring our tools to more manufacturers globally and invest in the development of new features, such as simulation based on causal machine learning.”

About EthonAI

EthonAI is an AI-powered platform that helps manufacturers boost performance by detecting, monitoring and preventing quality losses at scale. By aggregating process and quality data on a single platform, EthonAI’s advanced AI methods allow manufacturers to analyse and improve the quality of their products and processes. The platform offers a suite of no-code software tools for vision-based defect detection, process monitoring and root cause analysis. Using EthonAI, manufacturers have seen significant increases in productivity and an over-50-percent reduction in quality losses. This improves manufacturers’ financial performance and helps reduce environmental impact by reducing waste, rework and defects.